Technology - Breaking the Mould

TWIN BEAM PRINCIPLE

Conventional seat architecture is based upon a twin beam principle, usually tubes, one under the knees and one under, and behind, the bottom, at shin level. Some newer designs mount these beams closer together so that they sit more centrally under the passenger, but they still constrain the seat, which is fixed between these beams. If the back rest reclines at all, it is hinged about the aft beam, which is why it invades the space of the passenger behind so much when deployed.

CANTILEVER PRINCIPLE

Blue Sky's architecture is entirely different. To create more knee and leg room, the aft beam was raised above knee level. This allowed us to exploit the space created by the lumbar curve of the spine. But to be able to stretch one's legs out and access under-seat space, the forward beam had to move downward to allow the seat pan to move to a lower position. An inclined slide could now move the seat pan forward and downward, taking with it a hinged internal back rest to fully support the spine - only possible if the seat is cantilevered. It now became possible to mount this mechanism within a fixed back shell that doesn't need to recline into the space of the passenger behind. By locking or unlocking the mechanism it is now possible, for the first time ever, to vary the ratio of premium to economy seats on any flight according to passenger demand, without physically changing the seat pitch, driving ancillary revenue.

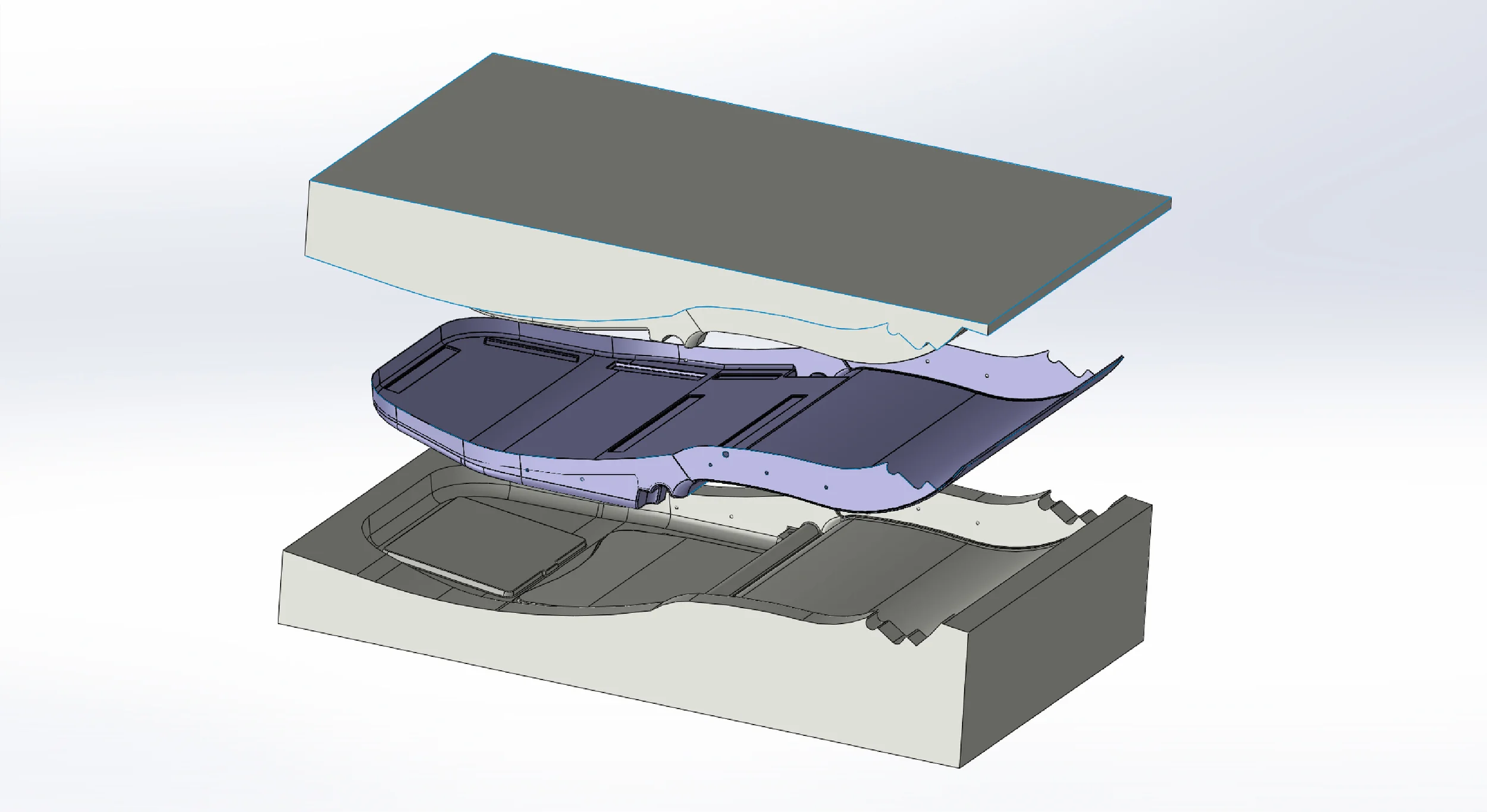

Technology - Carbon Moulding

OLDER TECHNOLOGY

Vacuum bag technology is slower and better suited to low volumes

Early woven fabrics needed filling, sanding and painting, adding weight and cost

FAST NEW TECHNOLOGY

New uni-directional fabrics permit custom orientation layup to match stress

Compression & Resin Transfer Moulding now matches injection moulding cycle times

Tools are locally heated with superheated steam for fast heat-up and cool-down

Tooling provides perfect repeatable mouldings with an 'A' surface on all faces

New HT (high toughness) epoxy resins are far stronger than steel and aluminium

HT snap cure epoxy resins replace phenolics and are fire, smoke and toxicity approved by FAA for aerospace

Technology - Intellectual Property

LICENCE

Blue Sky Aero owns a global Patent & Know How Licence to:

Exploit the technology

Grant Territorial Marketing / Manufacturing Licences

PATENTS AND REGISTERED DESIGNS

The Company owns a number of Patents and Registered Designs in Europe, USA & China

2017 Various patents in draft or pending

2015 Euro Patent - cantilever structure

2014 UK Patent - cantilever structure

2012 Grant of Design in China

2011 Registered Designs in Europe & USA

2005 UK Patent - mechanism & cantilever seat